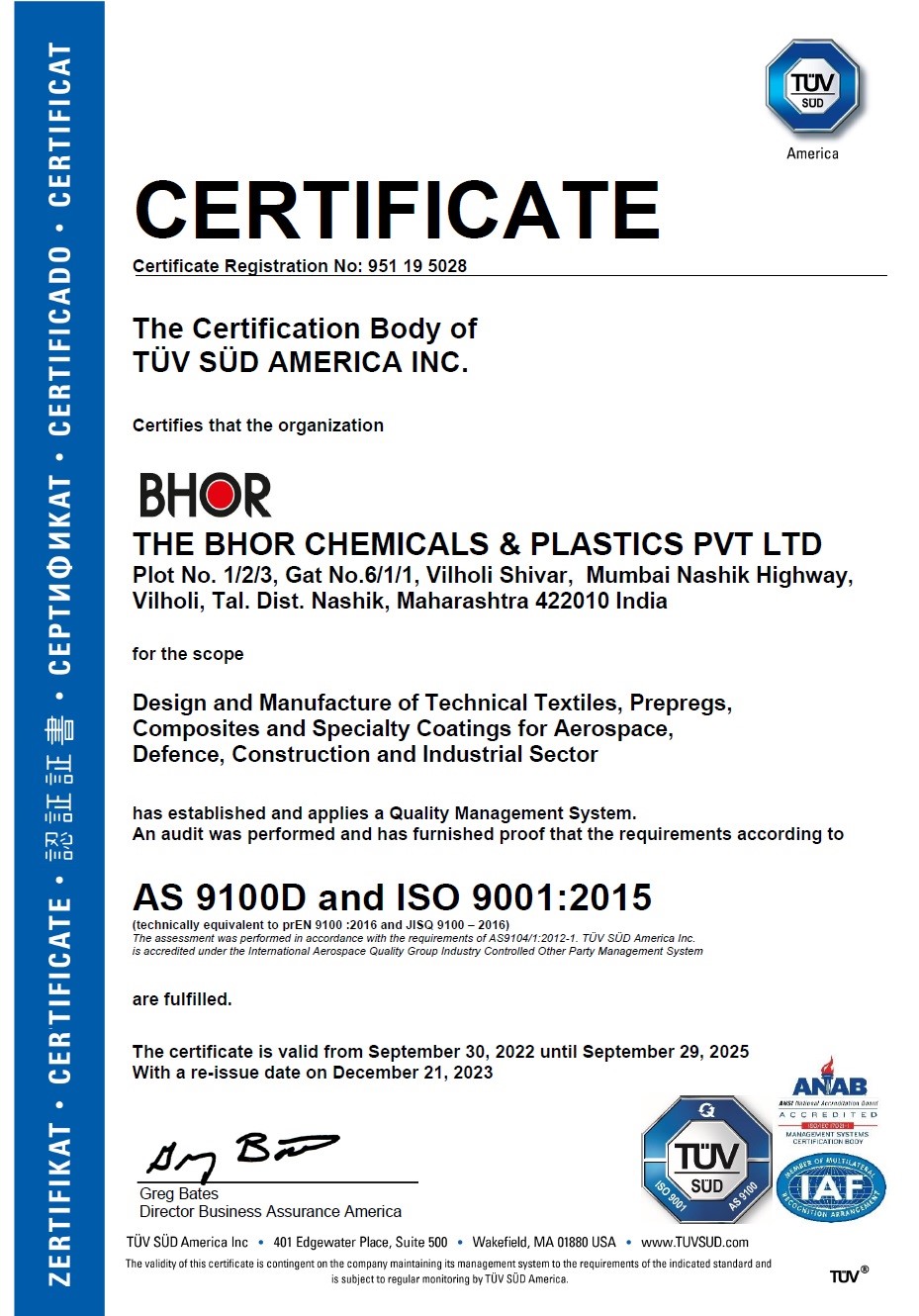

The Bhor Chemicals and Plastics Pvt. Ltd. stands as a premier carbon fiber intermediate manufacturer in India, delivering top-tier composite materials for industries including aerospace, structural strengthening, automotive, and unmanned systems. Our commitment to quality and innovation ensures that our products meet the rigorous demands of these sectors.

In addition to serving industrial clients, we cater to students and enthusiasts by offering a range of Composite Manufacturing Kits, fostering hands-on experience in advanced composite fabrication.

Our Product Portfolio